Our colour and writing products are manufactured in our workshops in Geneva since 1915.

- FREE GIFT WRAP AND PERSONALIZED MESSAGE. FREE DELIVERY ON ORDERS OVER £60.

THE SECRETS OF MAKING CARAN D'ACHE PENCILS

Did you know: each Caran d'Ache pencil goes through at least 35 steps in our fabrication process before it is allowed to glide across the paper. Many of these steps are performed by hand, as they have been for over a century, in our family-run factory in Geneva.

Follow in the footsteps of our technicians and explore the conscientious, local production behind our Swiss Made writing and drawing tools. From mixing pigments to cutting leads, varnishing and capping, the House of Caran d'Ache shares the secrets of manufacturing its graphite and coloured pencils.

INITIATIVES FOR LOCAL RAW MATERIALS

As wood is the essential raw material in pencils, it is of paramount importance to Caran d'Ache. Our Geneva-based company is committed to protecting the environment, and we aim to source more and more of our wood locally. Whenever possible, we are replacing our FSC (Forest Stewardship Council)-certified Californian cedar with certified Swiss wood. Local species – such as Scots pine, lime and alder – are being tested for use in our pencils. We are proud that the Swiss Wood pencil set, for example, is made entirely from local wood, a tribute to Switzerland’s natural beauty and respect for the environment.

COMMITMENT TO ECO-FRIENDLY MANUFACTURING

Since 2018, Caran d'Ache has been a signatory of the United Nations Global Compact, an initiative that encourages companies to adopt socially responsible behaviours. Our company complies with the ISO 9001 and ISO 14001 standards for quality and environmental management. In purchasing a Caran d'Ache pencil, you are supporting short supply chains and sustainability.

SWISS MADE PENCILS, TESTED AND COMPLIANT

In addition to being durable, Caran d'Ache pencils comply with European and American toxicity (AP) and health and safety (CE) regulations. The leads and pigments in our pencils pose no risk to children and are safe to handle. We have also developed a water-based varnish for almost all our pencils: an initiative that replaces the chemical solvents previously used.

WAX-BASED PIGMENTS AND LEADS

Caran d'Ache has been making coloured pencils, graphite pencils, pastels and gouaches with excellence for over 100 years. Appreciated by the greatest artists, Caran d'Ache produces more than 400 colours from a range of pure pigments. Each colour has a specific recipe, created in the Caran d’Ache research and development laboratory.

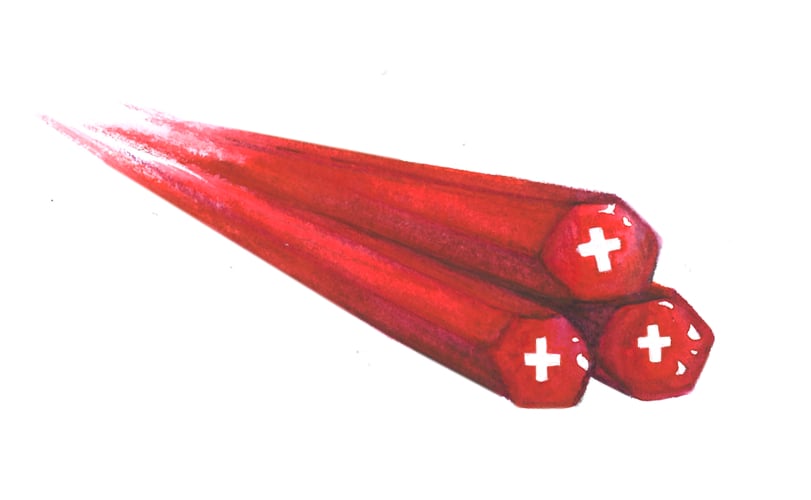

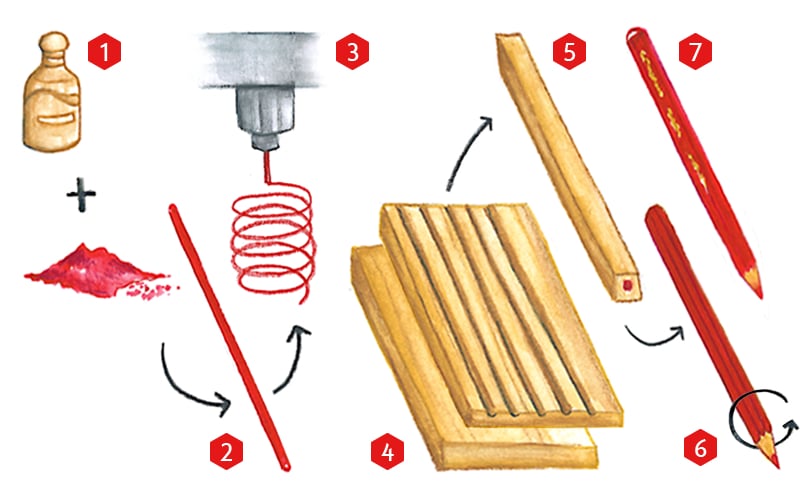

The lead in each pencil is made up of pigments, fillers and binders. During preparation, the powders and binders are diluted in water and mixed in precise proportions, depending on the desire colour. The mixture becomes a paste, which is then cut up into small pieces.

In a step called ‘spinning’, the paste is compressed and then extruded through the orifice of a piece of metal. A continuous ‘spaghetti’ of paste emerges at the desired diameter (the Prismalo pencil lead is thinner than the Luminance, for example). The spaghetti is cut to the length of the pencil and dried at a temperature over 100°C. After cooling, the leads are put into baskets and soaked in a melted wax bath for 24 hours.

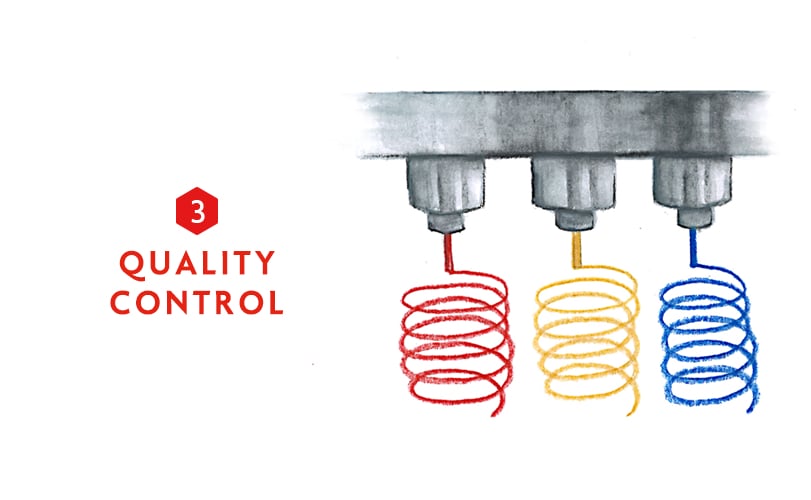

Once the leads have hardened, the laboratory performs quality control tests. In particular, the leads are subjected to breakage and wear tests. A special device breaks a sample of leads in order to measure the force required to break them, which must not be less than a certain benchmark. Ten other leads undergo a test of 10 metres of writing to measure their wear and hardness.

Wood arrives at the factory in planks that have to be planed and grooved. Glue is then applied to the grooved boards so that they can receive the leads. A second grooved board is then glued on top of the first to create a lead ‘sandwich’. The sandwiches are then pressed together to achieve optimum bonding before being cut into pencils.

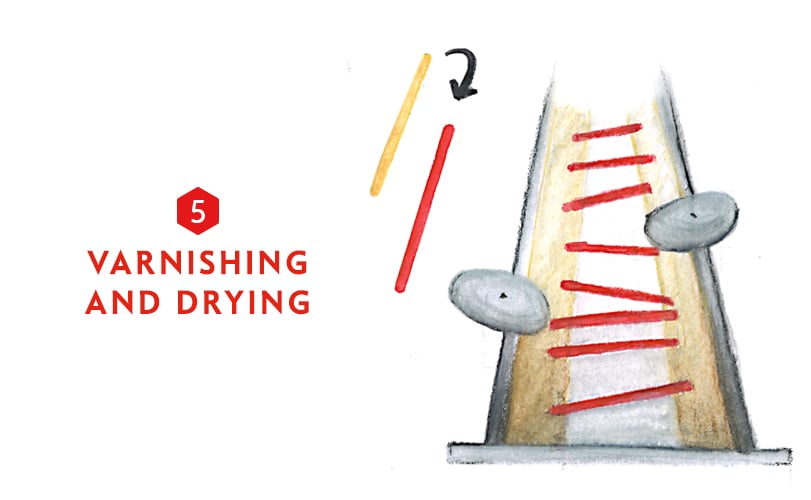

At this point, the pencils are still raw and retain their natural wood colour. To gain their finish, the pencils are passed through tanks of varnish. Each pencil will be coated with 6 layers of water-based varnish, each time traveling more than 40 metres on a drying belt before being transferred to the next machine. These machines are specially manufactured by Caran d'Ache, a testament to our engineering prowess.

The varnished pencils then undergo hotstamping on one to three sides, with the name of the company, the name of the product and any other essential information such as ‘Swiss Made’, the colour number or the bar code. Finally, the pencils are sharpened by a blade or run across an abrasive strip to give them their final tip, which is specific to each collection.

Capping consists of applying one or more layers of varnish to the top end of the pencils. Each category of pencil at Caran d’Ache has its own type of cap. Both practical and aesthetic, this step adds an elegant marker of a high-quality product. Several capping machines have been developed and manufactured on our premises.

After all these steps of production, the pencils still need to be visually inspected as they’re packed and boxed. In all, it takes around 50 hours to make a Caran d'Ache pencil.

Now you know what goes on behind the scenes of your exceptional Swiss Made pencils!

Free from 50£ purchase.

Possible return under 14 days.

Possible return under 14 days.

Monday to Friday from 10am to 7pm and Saturday from 10am to 5pm.

+41 (0) 848 558 558

(Calls from Switzerland : at local rate. Calls from abroad : at telecom provider’s international rate.)

+41 (0) 848 558 558

(Calls from Switzerland : at local rate. Calls from abroad : at telecom provider’s international rate.)

Deutschland

Deutschland Austria

Austria Belgium

Belgium Etats-Unis

Etats-Unis France

France Italy

Italy Japan

Japan Netherlands

Netherlands United Kingdom

United Kingdom Switzerland

Switzerland